Integrated production system with a monthly production capacity of two million meters

-

■ Integrated production system from bleaching to finishing

With a production system that realizes a one-stop dyeing process, we continuously carry out production at our own factory from bleaching to finishing. Our affiliated company, CHUGOKU BOSHOKU, which specializes in the weaving process, is also completely integrated with our production system. We have implemented a real-time production management system that shares information online by connecting our factory and offices resulting in high-quality dyed products with short delivery times.

-

■ A monthly production capacity of two million meters

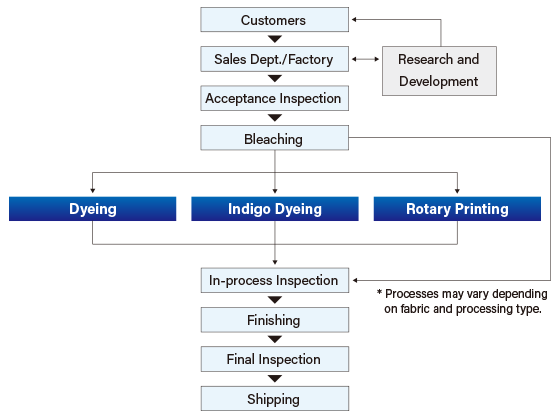

With one of Japan’s largest production facilities, we can produce two million meters a month. We can also flexibly respond to small lot orders even in a continuous processing factory. Our production system is reflected in the chart below.

Production system chart

Production equipment list

- Continuous scouring and bleaching machine [3 sets]

- Jet dyeing machine [4 units]

- Rotary printing machine [1 unit]

- Heat setting machine [1 unit]

- Shrink-proofing machine [3 units]

- Water pipe boiler [Heavy oil (15 tons)]

- Once-through boiler [Natural gas (17.5 tons)]

- Continuous dyeing machine [2 sets]

- Plain dyeing machine [2 units]

- Resin processing machine [3 units]

- Jigger dyeing machine [2 units]

- Raising machine [4 units]

- Industrial water purification apparatus 2,000 m3/day

- Automated bleaching agent blending apparatus (Computer Control Bleaching)

- Automated dye weighing apparatus (Computer Control Weighing)

- Automated reducing liquid blending apparatus (Computer Control Reduction)

- Factory wastewater treatment equipment 2,000 m3/day

- Computer color matching machine (Computer Color Matching)

- Automated dye blending apparatus (Computer Control Dyeing)

- Automated dyeing fluid blending apparatus (Computer Color Kitchen)

Copyright © SANYO SENKO Co., Ltd. All Rights Reserved.